Solutions

Horse Construction offers full range of structural strengthening materials with technical supports, documentation supports, products supports, project supports.

Applying carbon fiber without repairing cracks not only fails to achieve the desired reinforcement effect, but also conceals hidden dangers and accelerates deterioration. Furthermore, untreated cracks inevitably increase the risk of crack expansion. Both regulations and engineering practice require

Why is it not recommended to "apply carbon fiber without repairing cracks"?

The core contradiction lies in "failure of the reinforcement mechanism" and "amplification of hidden dangers"

The core principle of carbon fiber reinforced concrete is to tightly bond the carbon fiber sheet to the concrete through an adhesive, allowing the two to bear force synergistically. The high tensile strength of the carbon fiber is used to share the stress in the tensile zone of the beam, thereby improving the bearing capacity.

If the cracks are not repaired and the concrete is directly glued, this synergistic system will be fundamentally destroyed. Specific problems include:

Interfacial bonding failure renders the carbon fiber "useless."

Cracks create discontinuities on the concrete surface, preventing the adhesive between the carbon fiber sheet and the concrete from forming a complete bond. The adhesive at the crack easily seeps into the crack, resulting in a localized insufficient bond thickness. Alternatively, the concrete on either side of the crack cannot transfer stress to the carbon fiber sheet through the adhesive. Ultimately, the carbon fiber sheet cannot effectively participate in the load, significantly reducing its reinforcement effectiveness and even leading to sudden failure under load, such as "carbon fiber sheet delamination."

Moisture and harmful substances in cracks intrude, accelerating structural deterioration.

Unrepaired cracks serve as pathways for harmful substances like moisture, chloride ions, and carbon dioxide. These can lead to corrosion of the steel bars within the beam (the expansion of the bars further widens the cracks). Furthermore, they soften the adhesive, reducing its long-term bond strength and dramatically decreasing the durability of the reinforcement system. This can lead to more serious problems later, such as separation of the carbon fiber sheet from the concrete and concrete crumbling.

Covering up crack development poses a safety hazard.

After being applied, carbon fiber sheeting covers cracks, making it impossible to visually observe changes in crack width and length, and difficult to monitor their progression using testing methods (such as crack width meters). If cracks continue to expand due to stress or environmental factors, severe damage may occur within the beam even without noticeable damage to the carbon fiber sheeting, ultimately leading to sudden failure (such as beam fracture), creating uncontrollable risks.

Correct approach: Repair the cracks first, then paste the carbon fiber

According to the requirements of the "Concrete Structure Reinforcement Design Code", the cracks in the original beam must be treated before carbon fiber reinforcement. The core process is as follows:

1) Crack detection and classification: First, use crack width meters, ultrasonic testing, and other means to determine the crack width (e.g., ≤0.2mm, >0.2mm), length, depth (surface cracks, deep cracks, through cracks), and cause (stressed/non-stressed).

2) Targeted Repair:

Surface cracks/shrinkage cracks ≤ 0.2mm: Use pressure grouting to inject epoxy resin slurry to seal the cracks and prevent water intrusion.

Stress cracks/deep cracks > 0.2mm: First, remove the loose concrete on both sides of the crack to form a V-shaped groove. Then, insert a grouting pipe and inject structural adhesive (such as modified epoxy resin adhesive) under high pressure to ensure the crack is completely filled and restore the integrity of the concrete.

3) Interface treatment: After the cracks are repaired and cured (usually for more than 7 days to ensure that the colloid can be completely cured), the concrete surface is polished, dusted, and primed. Finally, carbon fiber cloth is pasted to ensure that the carbon fiber and concrete form a complete synergistic force system.

In summary, applying carbon fiber without repairing cracks not only fails to achieve the desired reinforcement effect, but also conceals hidden dangers and accelerates deterioration. Furthermore, untreated cracks inevitably increase the risk of crack expansion. Both regulations and engineering practice require "repair cracks first, then reinforcement."

You can find anything here you are in need of, have a trust trying on these products, you will find the big difference after that.

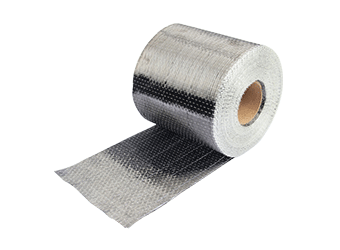

High strength, unidirectional carbon fiber wrap pre-saturated to form a carbon fiber reinforced polymer (CFRP) wrap used to strengthen structural concrete elements.

High strength crack sealing repairing adhesive for the fracture surface of concrete crack

Very strong penetration and low viscosity epoxy crack injection adhesive for repairing concrete crack